FlashCut Twins 3020 2B

FlashCut Twins 3020 2B

Conveyorized table

3050×2050 cutting area

3050×2050 collection area

50mm head height

Projector in the cutting area

EXAMPLES APPLICATIONS:

Automobil

Aeronautics

Militar

Upholstery

Composites

Gaphic Arts

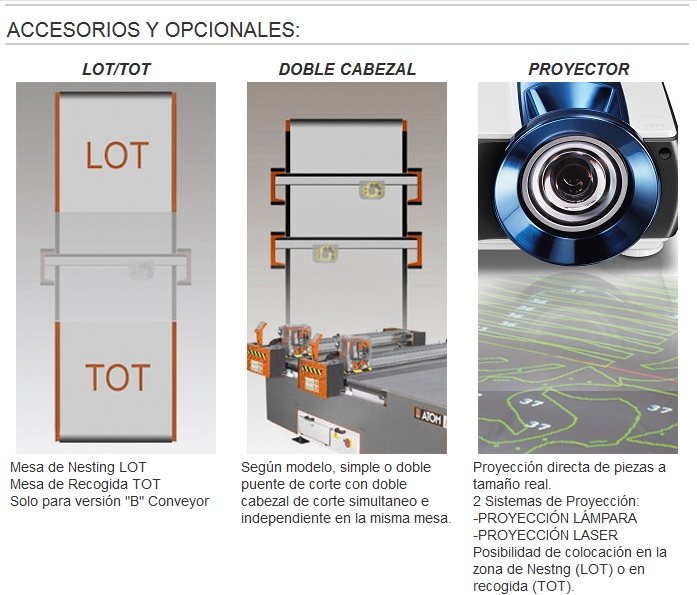

New generation of blade cutting systems FlashCut TWINS offers a wide range of configurations and accessories in order to satisfy the possibility of working a wide variety of flexible materials in many industrial sectors: Industrial Gaskets, Packaging, Upholstery, Automobile, Aeronautics, Composites, Footwear, Leather Goods, etc.

They represent the natural evolution of the previous generation of ATOM cutting systems, notably improving robustness always based on a solid and compact chassis, an exclusive Atom characteristic of recognized and proven efficiency.

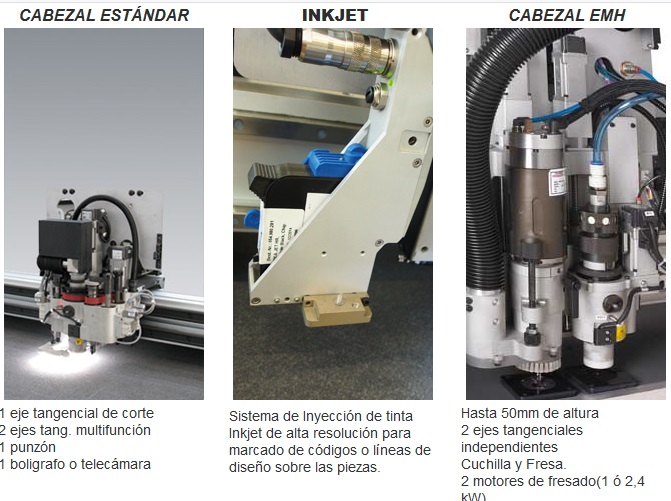

Solid chassis structure, precision mechanics and state-of-the-art electronics. Modular cutting head capable of handling materials up to 50mm thick. Said head is made up of 2 main tangential cutting tools that can be completed with optional accessories, which include inkjet printing and head telecamera for the recognition of pre-printed materials. Control of heights, speeds and regulations in the head are operated through the software.

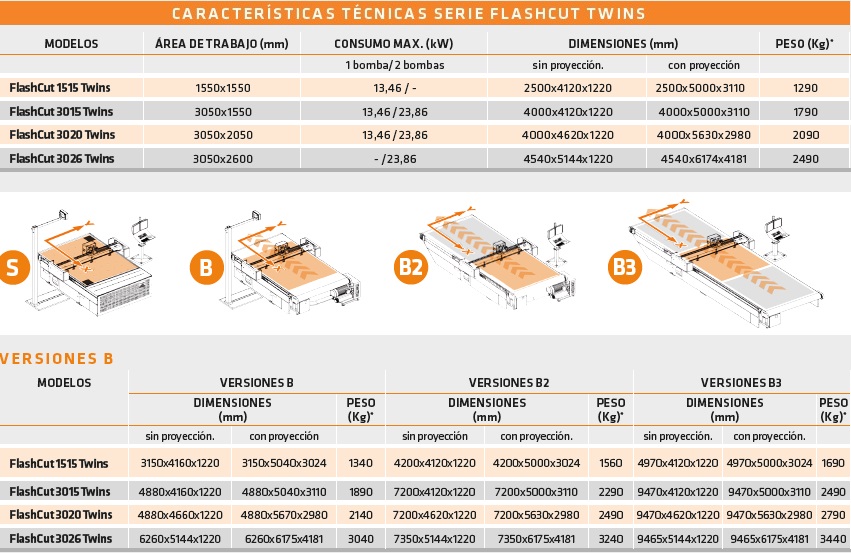

The TWINS line is divided into the following versions:

Flashcut «S»: Static cutting surface tables.

Flashcut «B»: Cutting surface tables with mobile mat. Conveyorized. For cutting rolls.

Flashcut «EMH»: Cutting tables with sequential head or separate tools Cutter / Cutter with a maximum height of 50mm.

Brochure Download: FlashCut TWINS